| product name | shock-proof air bubble sheet in roll |

| materials | PO |

| craft | heat seal |

| color | transparent |

| thickness | 20um |

| size before inflatable | L30*H40CM |

| size after inflatable | L26*H36CM |

| MOQ of spots goods | 200 rolls |

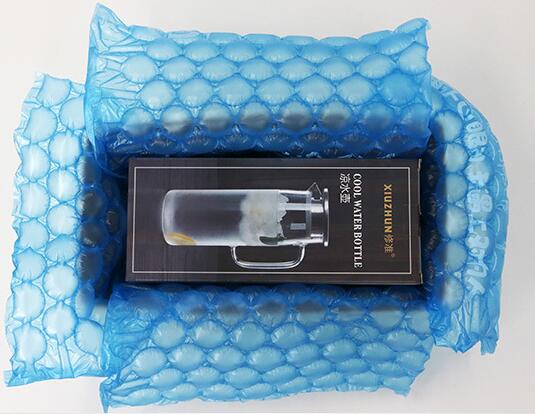

New types of cushion bag roll are widely used in electronics, instrumentation, ceramics, handicrafts, household appliances, kitchens, furniture. glass products and precision instruments etc shock-resistant cushioning packaging.

The new type of cushion bag roll is also called air cushion film, gourd bubble film and so on. It is processed with PO and PE materials. It is a soft packaging material commonly used at present.Its principle is that the film contains air to form bubbles to prevent product collision, to ensure that the product is shaken to play a protective role, but also has the role of thermal insulation.It can printing logo or choose colors,the fashionable appearance also can improve the image of products!

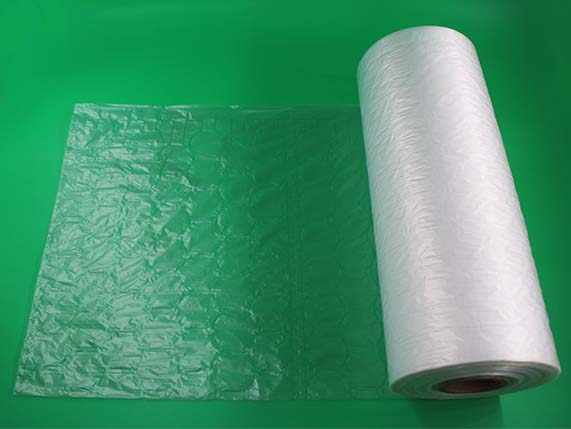

Before inflate

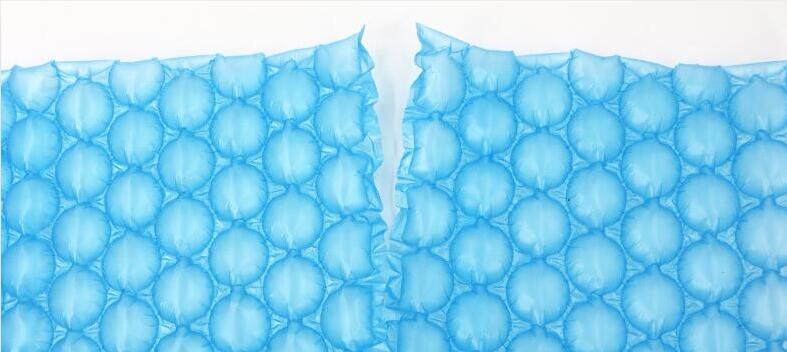

After inflate

Automatically inflatable machine

300m/1000pcs/roll(0.01m³/roll,4.7kg/roll include paper tube.)

1.Q:Does it must use be inflate by automatically machine?

A:Yes, it must be inflated with a special automatic inflate for gourd film.

2.Q:How to lock air after inflating?

A:It will seal while inflating.

3.Q:Does it need to be cut in the process of use?

A:No,there is a dashed line every 100 mm,, just tear it

4.Q:If tear it off by sheet, can it be used as an air bubble sheet?

A:Yes, it can also be used as an air sheet,the size of each sheet is 300mm*400mm.

5.Q: How many meters per roll of usually?

A:The meters usually is 300 per roll.

6.Q: How many pcs air bubble sheet of per roll?

A:Per roll usually is 1000 pcs air bubble sheet.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved