| product name | shock-proof air column roll |

| materials | PA+PE |

| craft | heat seal |

| color | transparent |

| thickness | 6um |

| size | L300*H0.3M/roll,or customized it. |

| MOQ | 3 rolls |

Conventional width of air column roll is 2 cm, 3 cm and 8 cm. The wider of air column, have better cushioning effect. But the most commonly used is 3 cm column width. Thickness also has 6um, 7um, 8um, the stronger thicker have better protective too . If you need customization, please contact us for discussion. It also can be tear or cut, will to pack vulnerable goods, such as glass crafts, express delivery, red wine, porcelain, precision instruments, etc.

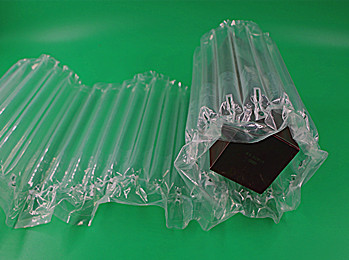

Before inflate

After inflate

Automaically inflatable machine

300m/roll(0.023m³/roll,10.2kg/roll include paper tube.)

1.Q:What inflatable tool can be use?

A:Air pump or automatic inflator.

2.Q:How to lock air after inflating?

A:No sealing is needed after inflating, and the air is locked by valve.

3.Q:HDoes it need to be cut in the process of use?

A:No,there is a dashed line every 200 mm , just tear it.

4.Q:If tear it off by sheet, can it be used as an air bubble sheet?

A:Yes, it can also be used as an air column sheet.

5.Q: How to lock air after inflating?

A:No sealing is needed after inflating, and the air is locked automatically. Our air valves are reverse valves, which make use of air pressure difference and high pressure to tighten the valves to prevent air leakage.

6.Q: How long can the air be stored after inflation?

A:After inflate, it can be storage for 3-6 months.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved