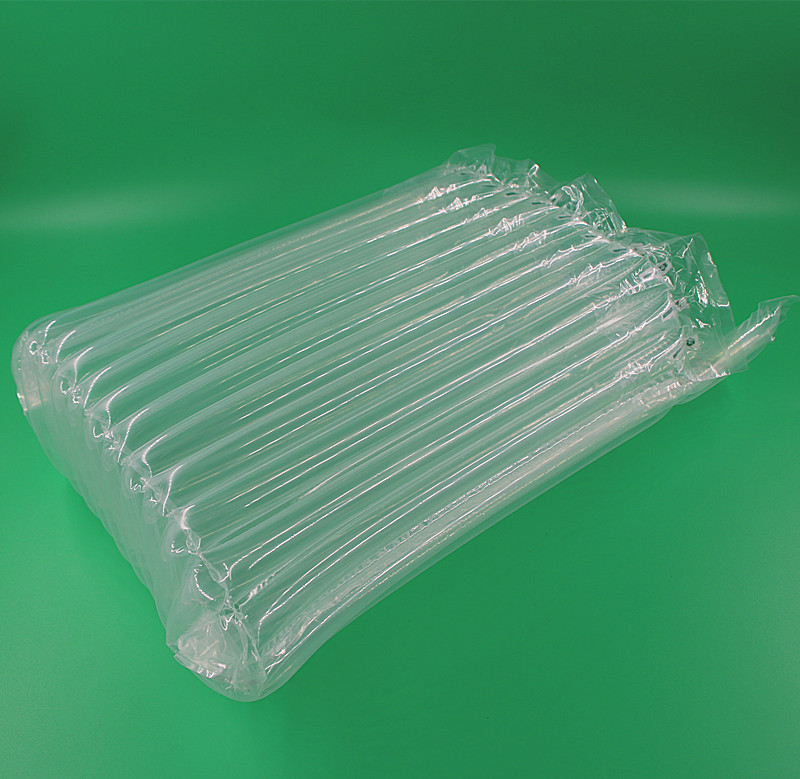

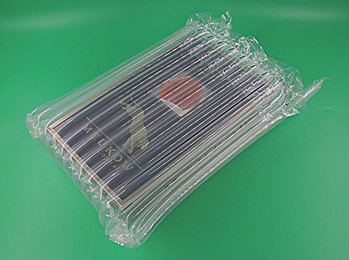

| product name | shock-proof whisky air column packing bag |

| materials | PE(polyethylene)+PA(nylon) |

| craft | heat seal |

| color | transparent |

| thickness | 60um |

| size before inflatable | L450*W0.24*H440MM |

| size after inflatable | L170*W80*H280MM |

| MOQ of spots goods | 3,000 pcs |

| customized | available |

| MOQ of customized | 10,000 pcs |

Why are the cushioning packaging materials of whisky bottles and other glass containers must use air column bags?

The frangibility of glass bottles has always been a serious problem that puzzles us. Many buyers will be surprised when they receive the products packed with glass bottles. Broken and broken bottles are also common, because the phenomenon of collision is inevitable. How can we reduce the breakage rate of glass bottles during transportation?

First of all, it is necessary to improve the production of glass bottles, add chemical raw materials to enhance their mechanical properties, enhance their strength and improve the production process, so as to avoid the damage caused by quality problems.

Then the packing material with high cushioning performance should also be used in the packing of the glass bottle. Using the air column bag or the gap void filling film can cover the glass bottle 360 ° in all directions, which can prevent the extrusion of the external force and effectively reduce 95% damage rate of the glass bottle in the transportation process.

Finally, transportation precautions: when transporting glass bottle products, the freight driver should try to choose a more stable road surface, move forward at a uniform speed, and reduce the emergency brake. When transferring, the workers should also pay attention to handle with care, so as to effectively avoid the damage caused by violent transportation.

So, how to make a suitable air cushion packaging for your products? Contact below, our gas column experts give you a comprehensive answer!

Email:sunshinepack688@gmail.com

Phone/WhatsApp/Wechat: +86 18926828072

a few pcs

700 pcs/carton(0.038m³/carton)

put goods into the bag,and tear it one by one

600pcs/roll(0.04m³/roll)

1.Q:What if the air can't into air column bag ?

A:Just a gentle rub of the valve will make the intake passage unobstructed.

2.Q:How to lock air after inflating?

A:No sealing is needed after inflating, and the air is locked automatically. Our air valves are reverse valves, which make use of air pressure difference and high pressure to tighten the valves to prevent air leakage.

3.Q:How long can the air be stored after inflation?

A:After inflate, it can be storage for 3-6 months.

4.Q:What about it have scratch leakage air?

A:After the single column is damaged and leaked air, it will not affect of other air columns. Other air columns can continue to protect the products.

5.Q: What's the maximum weight can it bear?

A:The maximum bear weight of it is 200 kg.

6.Q: Does it passed the environmental protection certification?

A:Yes,it already passed SGS environmental certification.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved