| product name | shock-proof air pillow cushion bag film |

| materials | PO |

| craft | heat seal |

| color | transparent |

| thickness | 20um |

| size before inflatable | L10*H20CM/bag |

| size after inflatable | L8*H16CM/bag |

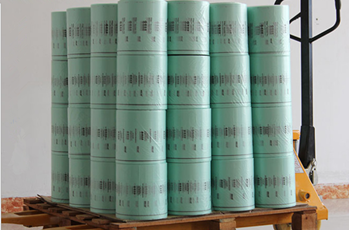

| MOQ of customized | 200 rolls |

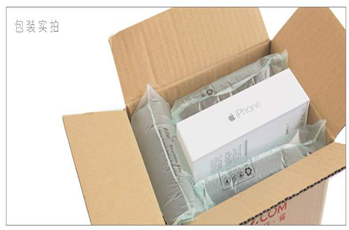

Products need to go through long-distance transportation, stacking, throwing and other processes in the transport process. It is easy to appear the phenomenon of product damage. So the packaging before shipment is very important. In addition to external packaging, cushioning packaging materials are also needed as a inner protection.

The air cushion bag is composed of air and film, which flushes air into the film to achieve the effect of buffer protection.

As a new cushioning packaging material,air cushion bag is used for filling the void in the box to avoid the collision caused by the shaking of the product in the course of transportation, resulting in product damage. Compared with traditional cushioning packaging material, air column bag has many advantages, such as light texture, good elasticity, strong toughness, and stronger protection of the product by increased bubbles.

Whether it is padding, wrapping, winding, or filling, it is very simple and convenient to use. How much do you need,then tear off how much, to improve packaging efficiency, without causing excessive packaging. The air cushion bag has strong plasticity and is suitable for the protection and packaging of all kinds of products. Its strong anti-collision and compression ability is favored by various industries.

Before inflate

After inflate

Automatically inflatable machine

500m/4166pcs/roll(0.007m³/roll,3.6kg/roll include paper tube.)

1.Q:Does it must use be inflate by automatically machine?

A:Yes, it must be inflated with a special automatic inflate for gourd film.

2.Q:How to lock air after inflating?

A:It will seal while inflating.

3.Q:Does it need to be cut in the process of use?

A:No,there is a dashed line every 120 mm, just tear it.

4.Q:If tear it off one by one, can it be used as an air column sheet?

A:Yes, it can also be used as an air column sheet,the size of each sheet is 120mm*200mm.

5.Q:Can we costomized our logo on this bag?

A:Yes, of course.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved