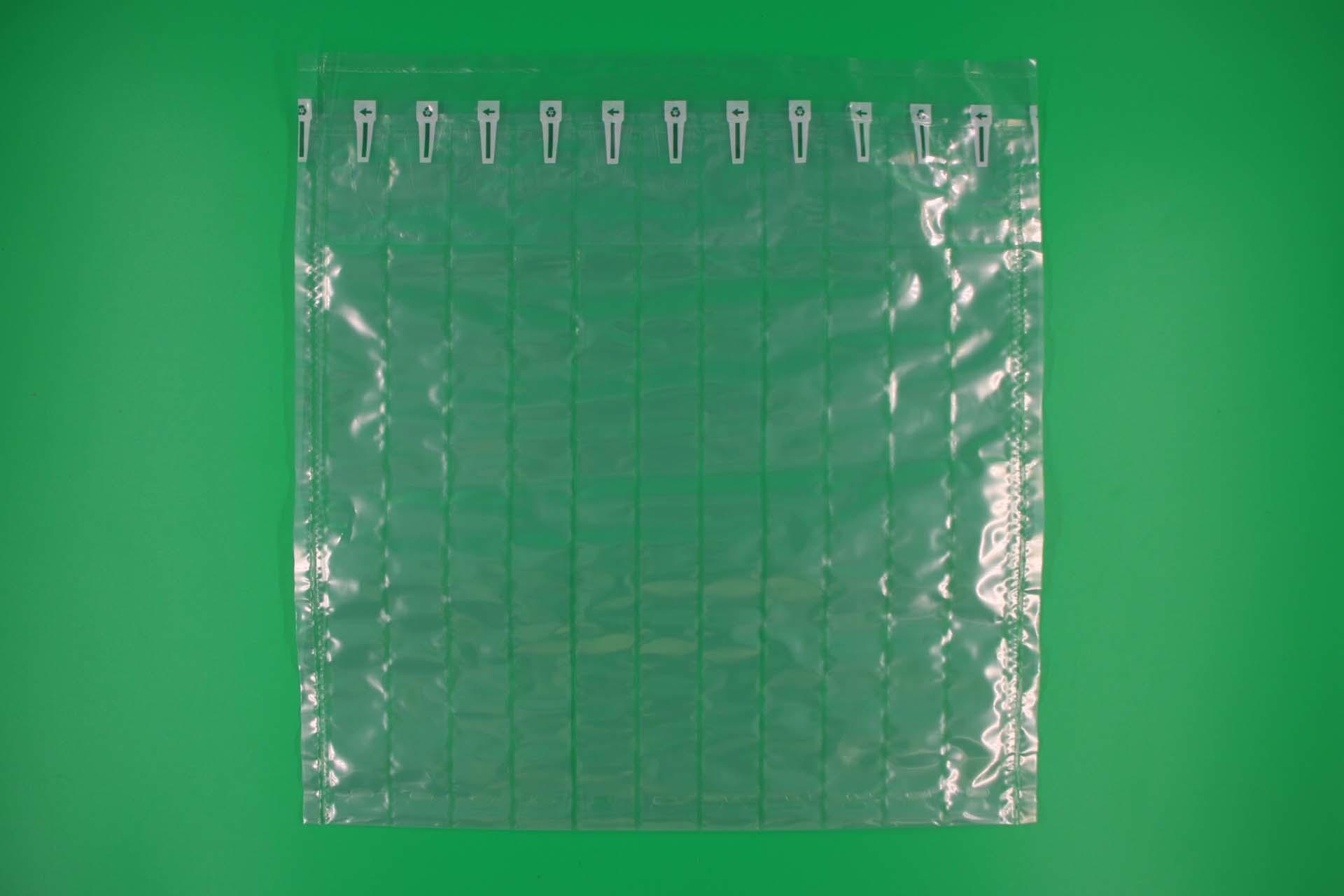

| product name | shock-proof ipaid air cushion packing bag |

| materials | PE(polyethylene)+PA(nylon) |

| craft | heat seal |

| color | transparent |

| thickness | 60um |

| size before inflate | L360*W0.24*H380MM/bag |

| inner size after inflate | L250*W25*H300MM/bag |

| MOQ of the size of spots goods | 3000 pcs |

| customized | available |

| MOQ of customized | 10000 pcs |

Electronic products as the most popular fast consumer products, in the booming sales at the same time, facing transportation is also a headache, because in the transport process will inevitably encounter some bumps, the product deformation or even crushing the probability is very high. Ipaid as a high-end electronic products, a good protective packaging can effectively solve the above problems, after effective testing, the use of air-column packaging can reduce the damage rate to 0.1% in the transport process, buyers enjoy the good of shopping experience, naturally praised constantly!

can pack by carton

or by roll

1.Q:Does it must use be inflate by automatically machine?

A:no,also can use air pump.

2.Q:How to lock air after inflating?

A:It will seal while inflating.

3.Q:Does it need to be seal in the process of use?

A:No,the valve will automatically lock the air.

4.Q:May i have a small test order?

A: Yes,first order we can accept a small quantity.

5.Q: How to lock air after inflating?

A: No sealing is needed after inflating, and the air is locked automatically. Our air valves are reverse valves, which make use of air pressure difference and high pressure to tighten the valves to prevent air leakage.

6.Q: How long can the air be stored after inflation?

A:After inflate, it can be storage for 3-6 months.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved