How much will it take for air conditioned pillow materials?

2021-02-17

While in the business of producing air conditioned pillow, the material cost can be one of the biggest expenses, directly affecting profitability. But it is possible to reduce material costs without compromising end product quality and changing customer expectations and dependencies. Like most effective commercial cost reduction measures, reducing commodity costs begins with a comprehensive analysis of the various direct and auxiliary ways in which cash flows from the underlying materials are consumed. Here lists some of the ways Dongguan Sunshinepack Industrial Co., Ltd. does to reduce materials cost, to bring benefits to both customers and ourselves: use the lower-cost alternatives if possible, reduce waste, eliminate unnecessary product features, etc.

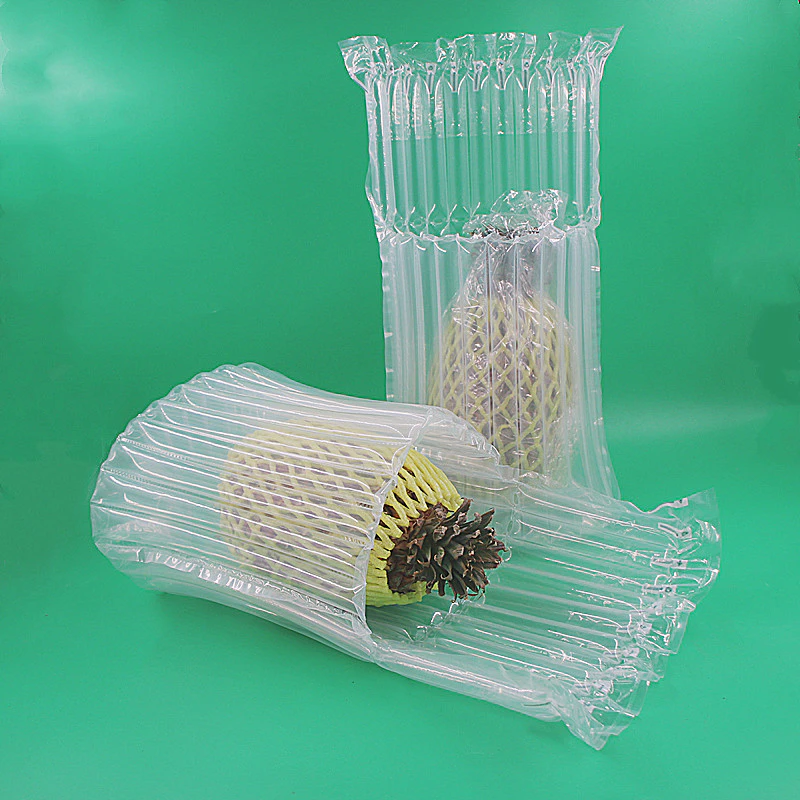

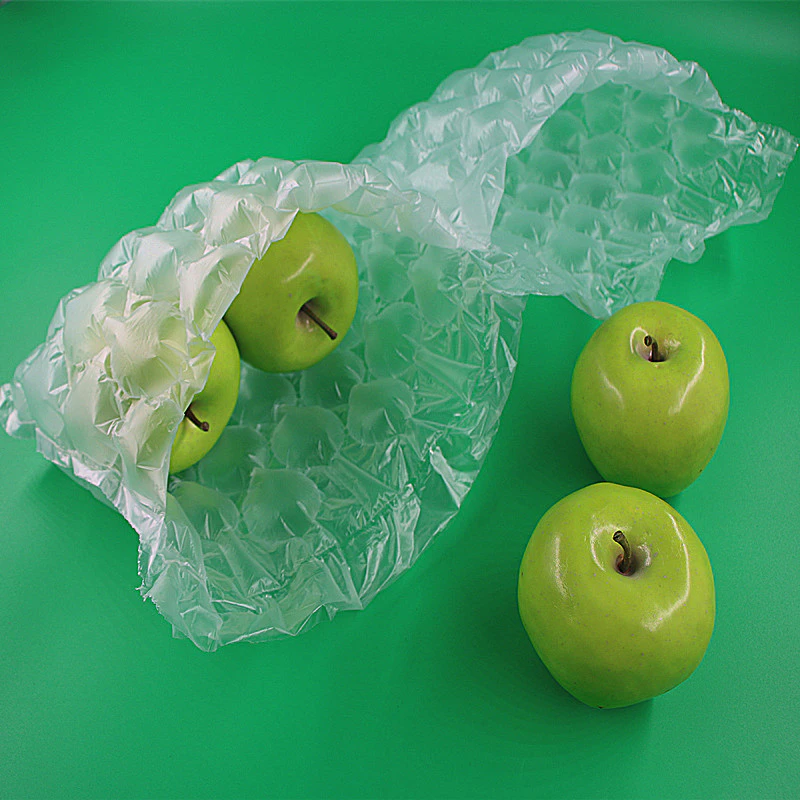

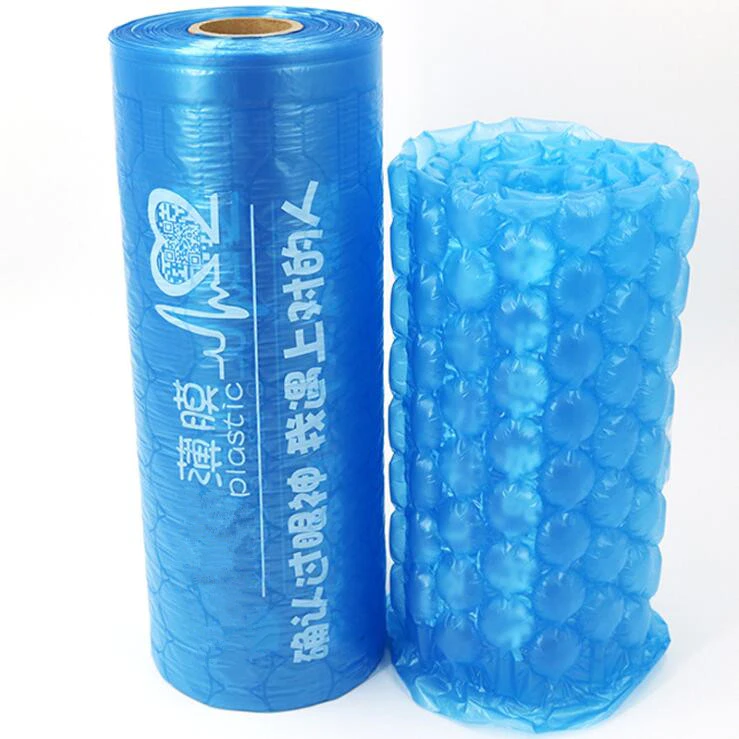

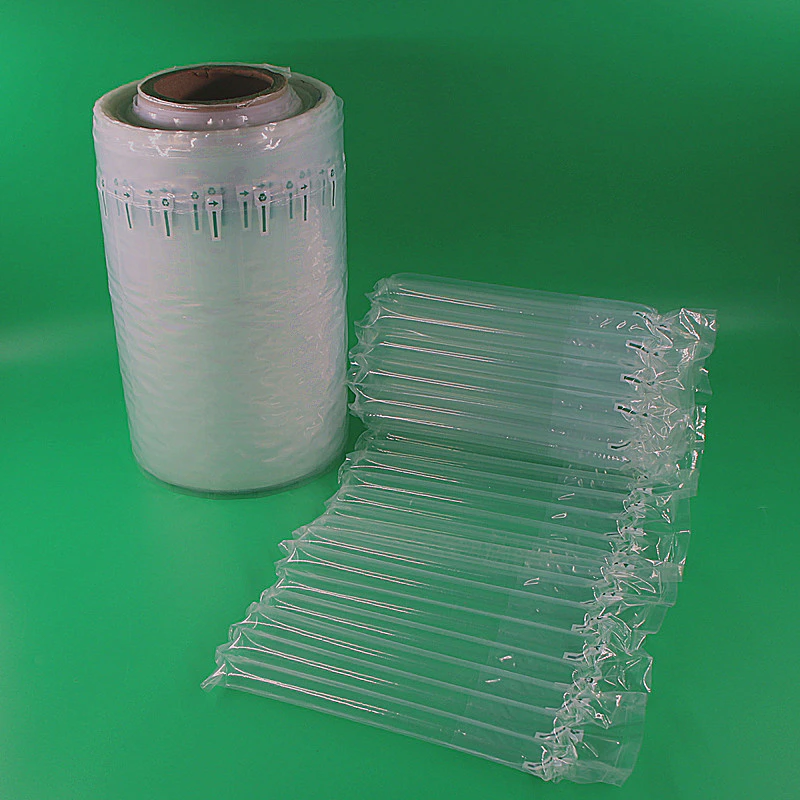

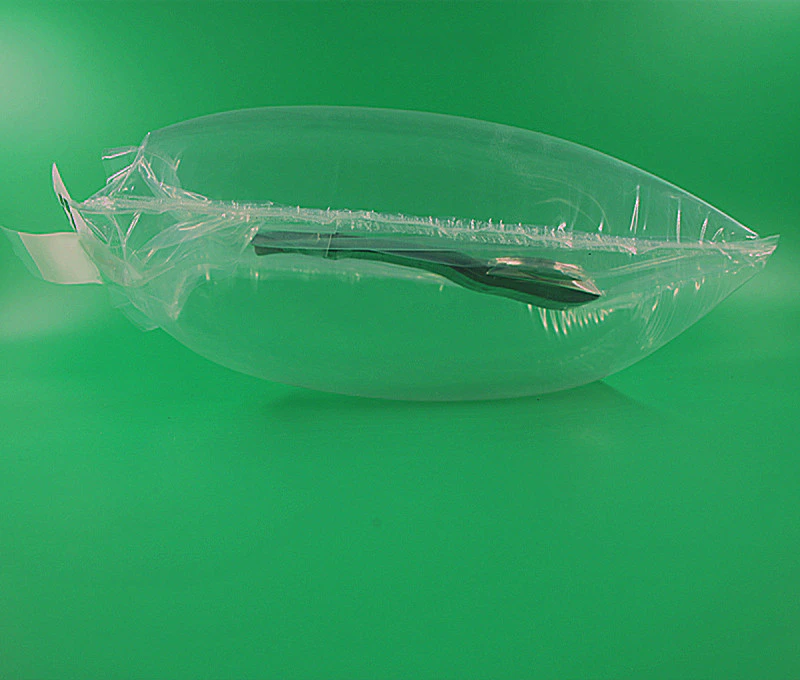

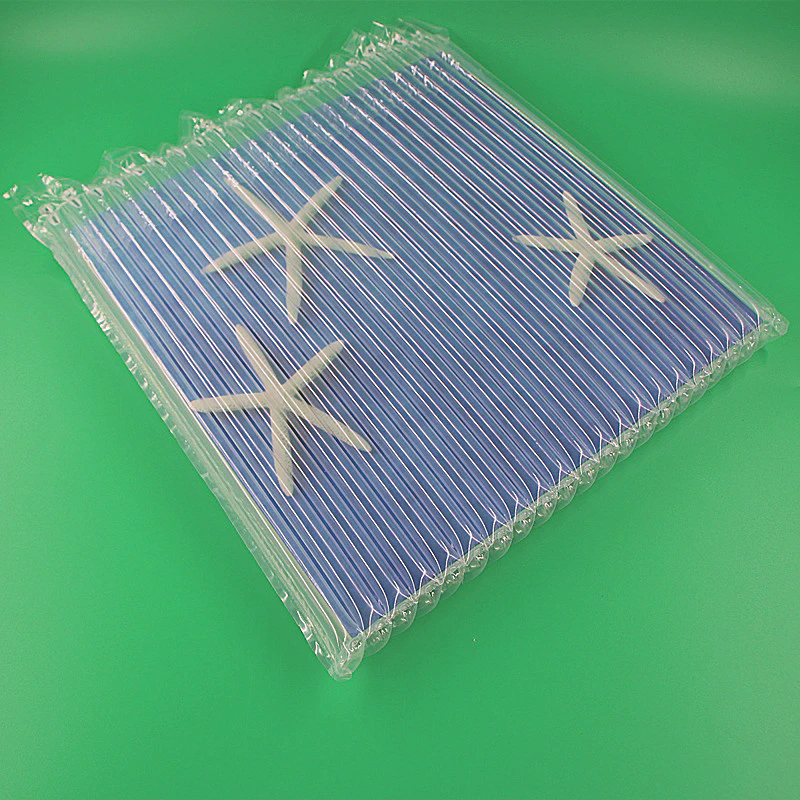

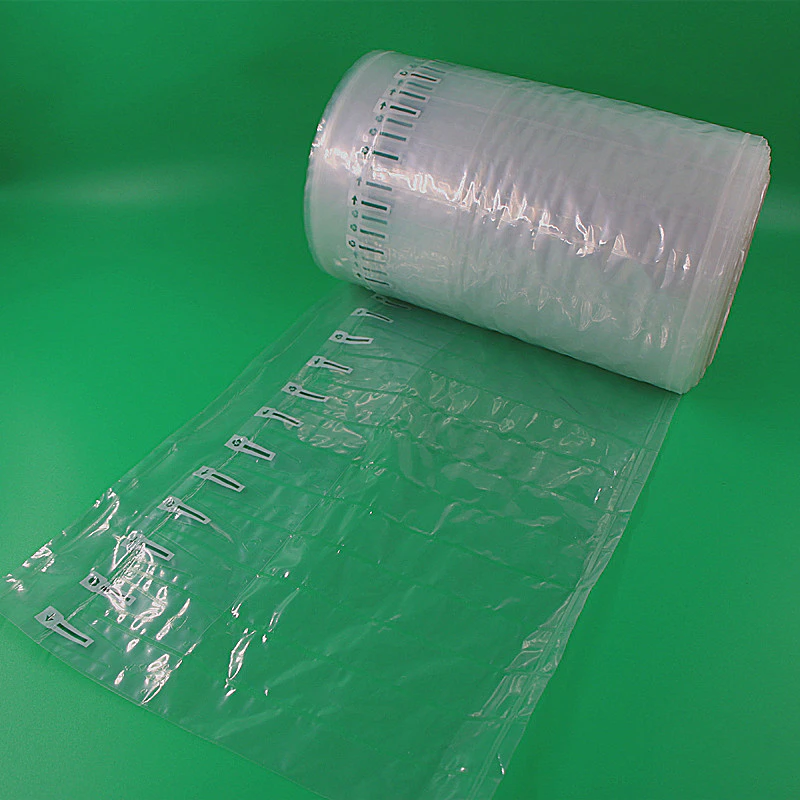

Dongguan Sunshinepack Co., Ltd is an experienced manufacturer. Over the years, we mainly focus on the developing, manufacturing, and exporting of air pouch packaging. Sunshinepack is mainly engaged in the business of air column roll and other product series. The production of Sunshinepack inflating machine is controlled and monitored by the computer. The computer exactly calculates the necessary amounts of raw materials, water, etc to reduce the unnecessary waste. It is the best-replaced choice of EPE foam and pulp plastic film. It offers an excellent solution to unsalable foodstuff. Crops will get rotten and wasted when they are in excess of demand, but dehydrating them by this product helps the foodstuff be stored for a much longer time. The product is inflatable and can be reused for many times.

For decades we have been providing sustainable products and services across the globe. We have actively reduced CO2 emissions during our production.

Dongguan Sunshinepack Co., Ltd is an experienced manufacturer. Over the years, we mainly focus on the developing, manufacturing, and exporting of air pouch packaging. Sunshinepack is mainly engaged in the business of air column roll and other product series. The production of Sunshinepack inflating machine is controlled and monitored by the computer. The computer exactly calculates the necessary amounts of raw materials, water, etc to reduce the unnecessary waste. It is the best-replaced choice of EPE foam and pulp plastic film. It offers an excellent solution to unsalable foodstuff. Crops will get rotten and wasted when they are in excess of demand, but dehydrating them by this product helps the foodstuff be stored for a much longer time. The product is inflatable and can be reused for many times.

For decades we have been providing sustainable products and services across the globe. We have actively reduced CO2 emissions during our production.