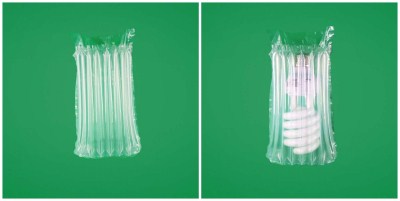

1. Q-type air column bag

This bag is easy to understand, just like the letter Q, no crack is exposed outside, so is the Q-type air column bag. In fact, it packs the product inside, the whole body of the product is packed in the air column bag, no point is exposed, really can achieve 360 degrees without dead angle for cushioning. Therefore, in logistics, some actions such as throwing, falling, smashing and throwing will not cause fatal damage to products. Because of the characteristics of Q-type air-column bag, it is most suitable for packaging fragile and fragile products made of glass bottles, red wine, electronic products, cosmetics and so on.

2. L-shaped air column bag

L-shaped air column bags, as its name implies, are shaped like L-shaped ones, with one side higher than the other, and then they can be packaged by gluing the space between the air column bags. The opening of this type of air column bags is suitable for tea products with relatively large sizes, such as milk powder, canned condiments, tea, storage tanks, large-diameter canned or boxed foods.

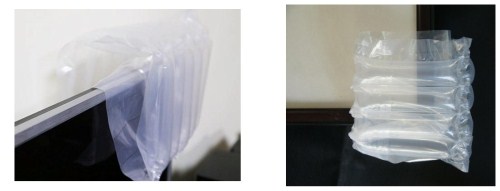

3. U-shaped air column bag

As the name implies, it is U-shaped bags without caps or hats. This type of bags are usually used in large-scale products, such as desktop computer screen packaging, TV packaging, photo frame packaging, large-scale crafts, etc. To sum up, such bags are suitable for packaging valuable, large-scale goods such as electronic screens. It is necessary to use such bags. It is easy to pack, and it will not cause damage. It is more safe and reliable than the previous foam cushioning material to package electronic screen, and the characteristics of green and environmental protection also make it even bigger.

4. Angle-protecting air column bag

The main function of the angle-protecting air column bag is to protect the edge and corner of the product and reduce the material damage caused by the impact of the edge and corner.

5. Air column sheet

Air column sheet is to cut the coil into sheet according to actual requirements,Cut neatly and beautifully, use conveniently and quickly, can be used as a gasket, self-wrapped articles use, high flexibility.Various widths can be customized,batch production , dimensional accuracy,which can cover the products closely and minimize the damage caused by transportation.

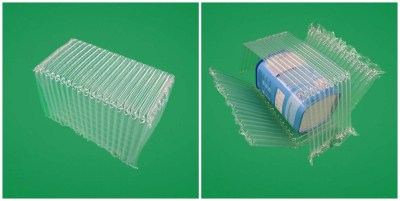

6. 360 degree cover of box

As the name implies, the 360 degree cover of box is to wrap the products 360 degree, The 360 degree cover of box is to use two pieces of air column sheets to wrap all the surfaces of the products.This kind of packaging is mainly used for the shock-proof cushion of large-sized cartons, such as computer packaging, machine equipment packaging, Installation, lamp packaging, etc. The greatest advantage of this kind of packing is that it can protect the cartons or products with neat edges and no voids.

7. Bags in Bags

This kind of bag is mainly made of four layers of film, and vacuum protection products are formed by inflating and extruding the inner bag. This kind of bag has thick air layer and strong impact resistance. It is mainly used in fragile products and food packaging which is difficult to transport, such as crystal cups, glass products, grapes, etc.

8. The filling bag

It is mainly round, square and rectangular. It is made of PE+PA 2 layer co-extrusion film to wrap air. It is often used for filling the gap of cartons to avoid the shaking and collision of goods in cartons. It is also used for filling and supporting the inside of schoolbag/backpack/bag/handbag, which is both beautiful and environmentally friendly. Bag type can be customized.

9. Cushioning bag in roll

This cushioning packaging material uses PO+PA, lightweight material. It is often used for filling the gap of cartons to avoid the shaking and collision of goods in cartons. Or directly used to wrap products, in the transport process can play a very good buffer protection effect! Compared with air filling bags, this cushion bag in roll has lower cost, lighter material, and it also meets the packaging needs, how much to will be use then tear how much,so there is no waste!

10. Air Bubble Film

The material of bubble film is PO+PA, which is lightweight and uses the design of bubbles to store air. It is widely used in packaging and filling of 70% of the products on the market. Bubble design makes the bubbles full and cushioning effect is better than traditional bubble paper.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved