| Product name | Multi-function automatically machine of air column film,U/L/Q style air column bag in roll series |

| Model no: | CLUQ-01 |

| Speed | 20m/min |

| Voltage | AC110v-AC220v |

| Materials | Metallic materials |

| G.W./N.W. | 53kg/60kg |

| Color | As pictures showed |

| Machine size | 60*60*65cm |

| Warranty | 12 month |

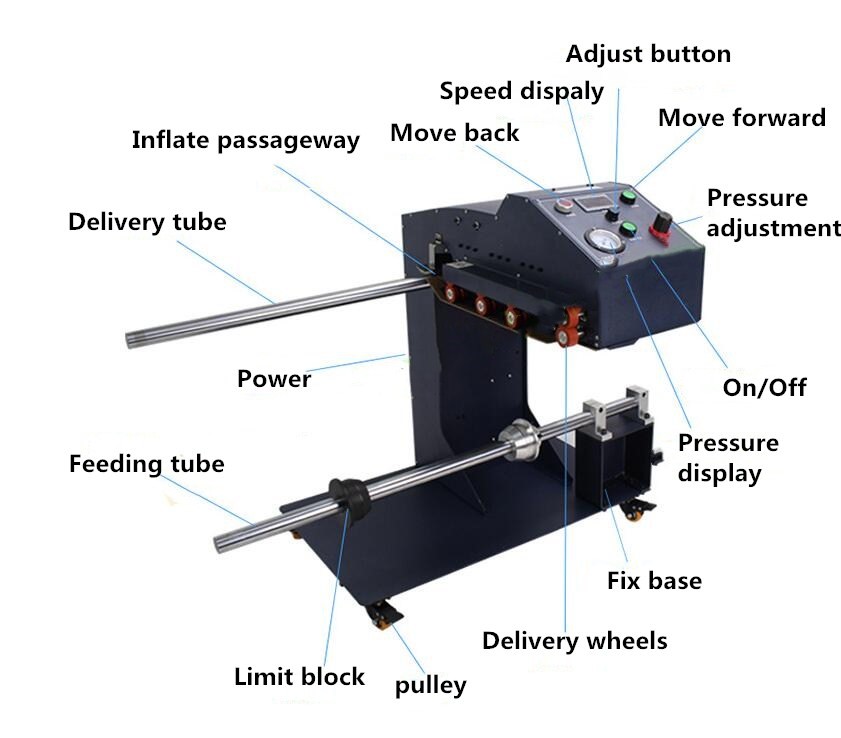

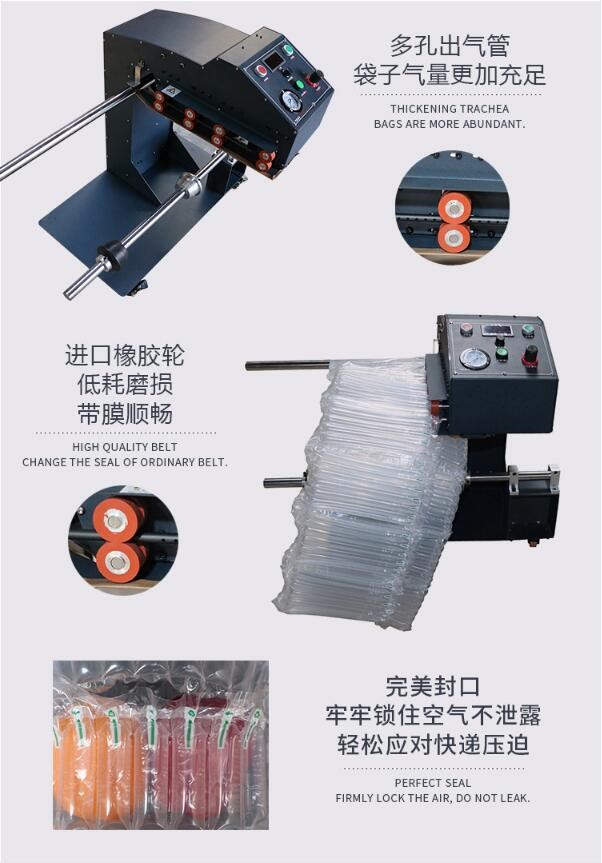

Air cushion bags and air bubble film series are now widely used in express packaging, logistics transportation, its cushioning effect has been recognized by many consumers. With the rapid development of express delivery and logistics industry, a good inflatable equipment is also essential! Not only can it help us to improve work efficiency and packaging process, save labor, but also save time! This inflator is made of metal material, which is light and beautiful. Temperature, speed, air volume can be adjusted, and the operating table is very simple and clear. Therefore, it can be applied to a variety of specifications of air cushioning packaging materials. Such as: filling bag, air bubble film, four-row exhaust air bubble film, two-row exhaust air bubble film, bubble film bag, honeycomb bag and so on. Fast inflation and with plump air!

1.Q:Does it need to be installed?

A:Yes, after receiving the machine, just follow the steps to install a few fittings.

2.Q:How does it inflate?

A:We installed an air pipe on the machine. When the power is connected, the air pipe will blow out the air.

3.Q:How does it lock air?

A:At the back of the air duct, we installed the heat sealing function. After inflating, we directly sealing without manual work.

4.Q:How to control the air volume and inflation speed?

A:Air volume and speed can be directly adjusted on the console of the machine.

5.Q: How long is the warranty period for the machine?

A: The warranty period is six months.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved